Joinery is a part of woodworking that involves joining together pieces of timber or lumber, to produce more complex items. Some wood joints employ fasteners, bindings, or adhesives, while others use only wood elements. The characteristics of wooden joints - strength, flexibility, toughness, appearance, etc. - derive from the properties of the materials involved and the purpose of the joint. Therefore, different joinery techniques are used to meet differing requirements. For example, the joinery used to construct a house can be different from that used to make puzzle toys, although some concepts overlap.

List of wood joints

Traditional ways of improving joints

Non-traditional ways of improving joints

Properties of Wood

Timber expands and contracts in response to humidity, usually much less so longitudinally than in the radial and tangential directions. As tracheophytes, trees have lignified tissues which transport resources such as water, minerals and photosynthetic products up and down the plant. While lumber from a harvested tree is no longer alive, these tissues still absorb and expel water causing swelling and shrinkage of the wood in kind with change in humidity. When the dimensional stability of the wood is paramount, quarter-sawn or rift-sawn lumber is preferred because its grain pattern is consistent and thus reacts less to humidity.

Materials used for joining

Traditional Joinery

Many traditional wood joinery techniques use the distinctive material properties of wood, often without resorting to mechanical fasteners or adhesives. While every culture in which pieces of wood are joined together to make furniture or structures has a joinery tradition, wood joinery techniques have been especially well documented and celebrated in the Indian, Chinese, European, and Japanese traditions. Because of the actual physical existence of Indian and Egyptian examples, we know that furniture from the first several dynasties show the use of complex joints, like the Dovetail, over 5 thousand years ago. This tradition continued to other later Western styles. The 18th century writer Diderot included over 90 detailed illustrations of wood joints in his comprehensive encyclopedia. While Western techniques focused on concealment of joinery, the Eastern societies, though later, did not attempt to "hide" their joints. The Japanese and Chinese traditions in particular required the use of hundreds of types of joints. The reason was that nails and glues used did not stand up well to the vastly fluctuating temperatures and humid weather conditions in most of Central and South-East Asia. As well, the highly resinous woods used in traditional Chinese furniture do not glue well, even if they are pre-cleaned with solvents and attached using modern glues.

Non traditional Joinery

Methods that are not considered traditional joinery have come about in modern times, largely to attempt to simplify the job of the woodworker for various reasons. These include biscuit joints and pocket hole joinery.

- Wikipedia

A worker uses a mortising machine to shape timber framing joints

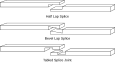

List of wood joints

A worker uses a large circular saw to cut joints.

Traditional woodworking joints

Non traditional wood working joints

Traditional ways of improving joints

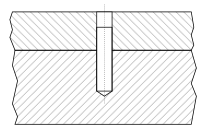

- Dowel : A small rod is used internal to a joint both to help align and to strengthen the joint. Traditional joints are used with natural timbers as they do not need any other materials other than the timber itself. for example: Butt joints. Dowel joints are also useful for pegging together weaker, cheaper composite materials such as laminate-faced chipboard, and where limited woodworking tools are available (since only simple drilled holes are needed to take the dowels).

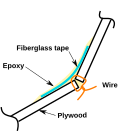

Non-traditional ways of improving joints

- Biscuit joints : A small 'biscuit' is used to help align an edge or butt joint when gluing.

- Domino joiner : A trademarked tool similar to a biscuit joiner, where a piece larger than a biscuit has some of the advantages of dowels, and some of the advantages of biscuits.

Properties of Wood

Many wood joinery techniques either depend upon or compensate for the fact that wood is anisotropic ; its material properties are different along different dimensions.

This must be taken into account when joining wood parts together, otherwise the joint is destined to fail. Gluing boards with the grain running perpendicular to each other is often the reason for split boards, or broken joints. Furniture from the 18th century, while made by master craftsmen, did not take this into account. The result is this masterful work suffers from broken bracket feet, which was often attached with a glue block which ran perpendicular to the base pieces. The glue blocks were fastened with both glue and nails, resulting in unequal expansion and contraction between the pieces. This was also the cause of splitting of wide boards, which were commonly used during that period.

In modern woodworking it is even more critical, as heating and air conditioning cause major changes in the moisture content of the wood. All woodworking joints must take these changes into account, and allow for the resulting movement.

Strength

Wood is stronger when stressed along the grain (longitudinally) than it is when stressed across the grain (radially and tangentially). Wood is a natural composite material; parallel strands of cellulose fibers are held together by a lignin binder. These long chains of fibers make the wood exceptionally strong by resisting stress and spreading the load over the length of the board. Furthermore, cellulose is tougher than lignin, a fact demonstrated by the relative ease with which wood can be split along the grain compared to across it.

Different species of wood have different strength levels, and the exact strength may vary from sample to sample.

Dimensional StabilityTimber expands and contracts in response to humidity, usually much less so longitudinally than in the radial and tangential directions. As tracheophytes, trees have lignified tissues which transport resources such as water, minerals and photosynthetic products up and down the plant. While lumber from a harvested tree is no longer alive, these tissues still absorb and expel water causing swelling and shrinkage of the wood in kind with change in humidity. When the dimensional stability of the wood is paramount, quarter-sawn or rift-sawn lumber is preferred because its grain pattern is consistent and thus reacts less to humidity.

Materials used for joining

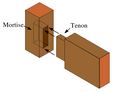

- Joints can be designed to hold without the use of glue or fasteners; a pinned mortise and tenon is an example of this.

- Glue is highly effective for joining timber when both surfaces of the joint are edge grain. A properly glued joint may be as strong or stronger than a single piece of wood. However, glue is notably less effective on end-grain surfaces. Animal glue is soluble in water, producing joints that can be disassembled using steam to soften the glue.

Metal plates are often incorporated into the design where the timber alone would not be strong enough for a given load

- Various mechanical fasteners may be used, the simplest being nails and screws. Glue and fasteners can be used together.

Traditional Joinery

Many traditional wood joinery techniques use the distinctive material properties of wood, often without resorting to mechanical fasteners or adhesives. While every culture in which pieces of wood are joined together to make furniture or structures has a joinery tradition, wood joinery techniques have been especially well documented and celebrated in the Indian, Chinese, European, and Japanese traditions. Because of the actual physical existence of Indian and Egyptian examples, we know that furniture from the first several dynasties show the use of complex joints, like the Dovetail, over 5 thousand years ago. This tradition continued to other later Western styles. The 18th century writer Diderot included over 90 detailed illustrations of wood joints in his comprehensive encyclopedia. While Western techniques focused on concealment of joinery, the Eastern societies, though later, did not attempt to "hide" their joints. The Japanese and Chinese traditions in particular required the use of hundreds of types of joints. The reason was that nails and glues used did not stand up well to the vastly fluctuating temperatures and humid weather conditions in most of Central and South-East Asia. As well, the highly resinous woods used in traditional Chinese furniture do not glue well, even if they are pre-cleaned with solvents and attached using modern glues.

Non traditional Joinery

Methods that are not considered traditional joinery have come about in modern times, largely to attempt to simplify the job of the woodworker for various reasons. These include biscuit joints and pocket hole joinery.

- Wikipedia