A hand plane is a tool for shaping wood. When powered by electricity, the tool may be called a planer. Planes are used to flatten, reduce the thickness of, and impart a smooth surface to a rough piece of lumber or timber. Planing is used to produce horizontal, vertical, or inclined flat surfaces on workpieces usually too large for shaping. Special types of planes are designed to cut joints or decorative mouldings.

A Japanese plane in use.

Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle to the cutting edge, render the planed surface very smooth. A cutter which extends below the bottom surface, or sole, of the plane slices off shavings of wood. A large, flat sole on a plane guides the cutter to remove only the highest parts of an imperfect surface, until, after several passes, the surface is flat and smooth. When used for flattening, bench planes with longer soles are preferred for boards with longer longitudinal dimensions. A longer sole registers against a greater portion of the board's face or edge surface which leads to a more consistently flat surface or straighter edge. Conversely, using a smaller plane allows for more localized low or high spots to remain.

Though most planes are pushed across a piece of wood, holding it with one or both hands, Japanese planes are pulled toward the body, not pushed away.

Woodworking machinery that perform the same function as hand planes include the jointer and the thickness planer, also called a thicknesser. When rough lumber is reduced to dimensional lumber, a large electric motor or internal combustion engine will drive a thickness planer that removes excess wood to create a uniform, smooth surface on all four sides of the lumber and may also plane the edges.

History

Hand planes are ancient, originating thousands of years ago. Early planes were made from wood with a rectangular slot or mortise cut across the center of the body. The cutting blade or iron was held in place with a wooden wedge. The wedge was tapped into the mortise and adjusted with a small mallet, a piece of scrap wood or with the heel of the user's hand. Planes of this type have been found in excavations of old sites as well as drawings of woodworking from medieval Europe and Asia. The earliest known examples of the woodworking plane have been found in Pompeii although other Roman examples have been unearthed in Britain and Germany. The Roman planes resemble modern planes in essential function, most having iron wrapping a wooden core top, bottom, front and rear and an iron blade secured with a wedge. One example found in Cologne has a body made entirely of bronze without a wooden core. A Roman plane iron used for cutting moldings was found in Newstead, England. Histories prior to these examples are not clear although furniture pieces and other woodwork found in Egyptian tombs show surfaces carefully smoothed with some manner of cutting edge or scraping tool. There are suggestions that the earliest planes were simply wooden blocks fastened to the soles of adzes to effect greater control of the cutting action.

A pair of wooden planes found on board the 16th century carrack, Mary Rose.

In the mid-1860s, Leonard Bailey began producing a line of cast iron-bodied hand planes, the patents for which were later purchased by Stanley Rule & Level, now Stanley Works. The original Bailey designs were further evolved and added to by Justus Traut and others at Stanley Rule & Level. The Bailey and Bedrock designs became the basis for most modern metal hand plane designs manufactured today. The Bailey design is still manufactured by Stanley Works.

In 1918 an air-powered handheld planing tool was developed to reduce shipbuilding labor during World War I. The air-driven cutter spun at 8000 to 15000 rpm and allowed one man to do the planing work of fifteen men who used manual tools.

Modern hand planes are made from wood, ductile iron or bronze which produces a tool that is heavier and will not rust.

Parts

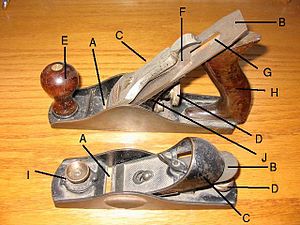

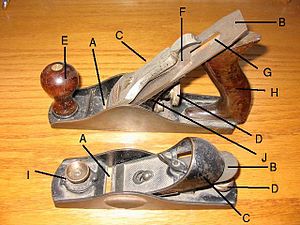

Parts of a plane

Two styles of plane are shown with some parts labeled. The top of the image is a bench plane; the bottom is a block plane.

A bench plane iron with chip-breaker.

- A: The mouth is an opening in the bottom of the plane down through which the blade extends, and up through which wood shavings pass.

- B: The iron is a plate of steel with a sharpened edge which cuts the wood. Some people refer to it as the blade.

- C: The lever cap holds the blade down firmly to the body of the plane.

- D: The depth adjustment knob controls how far the blade extends through the mouth.

- E: The knob is a handle on the front of the plane.

- F: The chipbreaker or Cap iron serves to make the blade more rigid and to curl and break apart wood shavings as they pass through the mouth.

- G: The lateral adjustment lever is used to adjust the iron by skewing it so that the depth of cut is uniform across the mouth.

- H: The tote is a handle on the rear of the plane.(Some aficionados object to the use of the word tote preferring handle).

- I: The finger rest knob Block planes are held in the palm of the hand while the tip of the user's index finger rests in the indentation on top of the knob. On some planes the knob is used to adjust the size of the mouth by allowing a sliding portion of the sole to be moved back or forward to accomplish this.

- J: The frog is a sliding iron wedge that holds the plane iron at the proper angle. It slides to adjust the gap between the cutting edge and the front of the mouth. The frog is screwed down to the inside of the sole through two parallel slots and on many planes is only adjustable with a screwdriver when the plane iron is removed. Some planes, such as the Stanley Bedrock line and the bench planes made by Lie-Nielsen and WoodRiver/Woodcraft Have a screw mechanism that allows the frog to be adjusted without removing the blade.

- The sole is the bottom face of the plane that slides against the wood.

Types

Most planes are broadly categorized as either bench planes, block planes, or specialty planes. In modern-day carpentry, electrically powered hand planers (also called hand or handheld power planers or simply power planes) have joined the family.

Modern wooden plane.

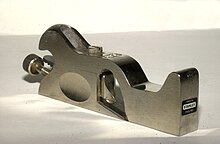

Bench planes are characterized by the cutting iron bedded with the bevel facing down and attached to a chipbreaker. Most metal bench planes, and some larger wooden ones, are designed with a rear handle known as a tote. Block planes are characterized by the absence of a chipbreaker and the cutting iron bedded with the bevel up. The block plane is usually a smaller tool that can be held with one hand and is used for general purpose work such as taking down a knot in the wood, smoothing small pieces, chamfering edges, and making the end of a sawed board square and smooth.

Different types of bench planes are designed to perform different tasks, with the name and size of the plane being defined by the use. Bailey iron bench planes were designated by number respective to the length of the plane. This has carried over through the type, regardless of manufacturer. A No. 1 plane is but little more than five inches long. A typical smoothing plane (approx. nine inches) is usually a No. 4, jack planes at about fourteen inches are No. 5, an eighteen inch foreplane will be a No. 6, and the jointer planes at twenty-two to twenty-four inches in length are No. 7 or 8 respectively. A designation, such as No. 4½ indicates a plane of No. 4 length but slightly wider. A designation, such as 5-1/2 indicates the length of a No. 5 but slightly wider (actually, the width of a No. 6 or a No. 7), while a designation, such as 5-1/4 indicates the length of a No. 5 but slightly narrower (actually, the width of a No. 3). "Bedrock" versions of the above are simply 600 added to the base number (although no "601" was ever produced, such plane is indeed available from specialist dealers; 602 through 608, including all the fractionals, were made).

A typical order of use in flattening, truing, and smoothing a rough sawn board might be:

- A scrub plane, which removes large amounts of wood quickly, is typically around 9 inches (230 mm) long, but narrower than a smoothing plane, has an iron with a curved cutting edge, and has a wider mouth opening to accommodate the ejection of thicker shavings/chips.

Planes may also be classified by the material of which they are constructed:

- A wooden plane is entirely wood except for the blade. The iron is held into the plane with a wooden wedge, and is adjusted by striking the plane with a hammer.

- A transitional plane has a wooden body with a metal casting set in it to hold and adjust the blade.

- A metal plane is largely constructed of metal, except, perhaps, for the handles.

- An infill plane has a body of metal filled with very dense and hard wood on which the blade rests and the handles are formed. They are typically of English or Scottish manufacture. They are prized for their ability to smooth difficult grained woods when set very finely.

A smoothing plane.

- A side-escapement plane, has a tall, narrow, wooden body with an iron held in place by a wedge. They are characterized by the method of shaving ejection. Instead of being expelled from the center of the plane and exiting from the top, these planes have a slit in the side by which the shaving is ejected. On some variations, the slit is accompanied by a circular bevel, cut in the side of the plane which causes the shaving to eject to the side through the open body of the plane.

Some special types of planes include:

Stanley No. 92 Rabbet Plane.

- The rabbet plane, also known as a rebate or openside plane, which cuts rabbets (rebates) i.e. shoulders, or steps.

- The spokeshave, is held horizontally by two symmetrical handles in line with the cutting edge of the iron. It has a very short sole, either flat, concave, or convex and is used for smoothing curved surfaces such as wagon spokes or tool handles.

- The fillister plane, similar to a rabbet plane, with a fence that registers on the board's edge to cut rabbets with an accurate width.

- The moulding plane which is used to cut mouldings along the edge of a board.

- The grooving plane which is used to cut grooves along the edge of a board for joining. Grooves are the same as dadoes/housings, but are being distinguished by running with the grain.

Router plane.

- The plow/plough plane, which cuts grooves and dadoes (housings) not in direct contact with the edge of the board.

- The finger plane, which is used for smoothing very small pieces such as toy parts, very thin strips of wood, etc. The very small curved bottom varieties are known as violin makers planes and are used in making stringed instruments.

- The bullnose plane, has a very short leading edge to its body, and so can be used in tight spaces; most commonly of the shoulder and rabbet variety. some bullnose planes have a removable toe so that they can pull double duty as a chisel plane.

- The combination plane, which combines the function of moulding and rabbet planes, which has different cutters and adjustments.

Stanley No. 55 Combination Plane.

- The circular or compass plane, which utilizes an adjustment system to control the flex on a steel sheet sole and create a uniform curve. A concave setting permits great control for planing large curves, like table sides or chair arms, and the convex works well for chair arms, legs and backs, and other applications.

- The toothed plane, which is used for smoothing wood with irregular grain. and for preparing stock for traditional hammer veneering applications.

- The spar plane, which is used for smoothing round shapes, like boat masts and chair legs.

- The match plane, which is used for making tongue and groove boards.

- Hollows and Rounds, which are similar to moulding planes, but lack a specific moulding profile. Instead, they cut either a simple concave or convex shape on the face or edge of a board to create a single element of a complex-profile moulding. They are used in pairs or sets of various sizes to create moulding profile elements such as fillets, coves, bullnoses, thumbnails ovolos, ogees, etc. When making mouldings, hollows and rounds must be used together to create the several shapes of the profile. However, they may be used as a single plane to create a simple decorative cove or round-over on the edge of a board. Many of these holes and rounds can be classified in the category of side-escampement planes.

Use

Planing wood along its side grain should result in thin shavings rising above the surface of the wood as the edge of the plane iron is pushed forward, leaving a smooth surface, but sometimes splintering occurs. This is largely a matter of cutting with the grain or against the grain respectively, referring to the side grain of the piece of wood being worked.

Planing with the grain.

The grain direction can be determined by looking at the edge or side of the work piece. Wood fibers can be seen running out to the surface that is being planed. When the fibers meet the work surface it looks like the point of an arrow that indicates the direction. With some very figured and difficult woods, the grain runs in many directions and therefore working against the grain is inevitable. In this case, a very sharp and finely-set blade is required.

When planing against the grain, the wood fibers are lifted by the plane iron, resulting in a jagged finish, called tearout. Planing against the grain in this manner is sometimes called "traverse" or "transverse" planing.

Planing against the grain.

Planing the end grain of the board involves different techniques, and frequently different planes designed for working end grain. Block planes and other bevel-up planes are often effective in planing the difficult nature of end grain. These planes are usually designed to use an iron bedded at a "low angle," typically about 12 degrees.

References

- ^ C. W. Hampton, E. Clifford: "Planecraft", page 9. C. and J. Hampton Ltd. 1959

- ^ Henry C. Mercer: "Ancient Carpenters' Tools", page 16. Bucks County Historical Society. 1975

- ^ Planing Ship Timbers with Little Machines, Popular Science monthly, December 1918, page 68, Scanned by Google Books: http://books.google.com/books?id=EikDAAAAMBAJ&pg=PA68.

- ^ "Toothed Plane". ECE.

- ^ "Shaping plane for rounding a spar".

- ^ "Stanley No. 148 Match Plane".

Bibliography

- Greber, Josef M. (1956 reprinted 1987) Die Geschichte des Hobels von der Steinheit bis zur Enstehung der Holzwerkzeugfabriken im frühen 19. Jahrhundert, Zurich, reprinted Hanover

- Greber, Josef M., transl. by Seth W. Burchard (1991) The History of the Woodworking Plane from the Stone Age to the Development of Woodworking Factories in the Early 19th Century, Albany, NY

- Hack, Garrett (1997) The Handplane Book. ISBN 1-56158-155-0.

- Hoadley, R. Bruce (2000) Understanding Wood: A Craftsman’s Guide to Wood Technology.ISBN 1-56158-358-8.

- Russell, David R., with Robert Lesage and photographs by James Austin, cataloguing assisted by Peter Hackett (2010) Antique Woodworking Tools: Their Craftsmanship from the Earliest Times to the Twentieth Century, Cambridge: John Adamson ISBN 978-1-898565-05-5.

- Salaman, R. A. (1989) Dictionary of Woodworking Tools. ISBN 0-04-440256-2.

- Todd, R., Allen, D., Alting, L., Manufacturing Processes Reference Guide, p. 124, 1994

- Watson, Aldren A. (1982) Hand Tools: Their Ways and Workings. ISBN 1-55821-224-8.

- Whelan, John M. (1993) The Wooden Plane: Its History, Form and Function Mendham, NJ: Astragal Press ISBN 978-1-879335-32-5.

External Links

- Handplane Central, Information for all types of hand planes, including wooden planes, infill planes and Stanley type planes. Also information on how to make hand planes.

- Catalog of American Patented Antique Tools, A pictorial collection of antique planes and other tools showing some of the variety in styles.

- The history, types, collector value and other information on the British hand plane maker Record Planes.

- Wikipedia